FORVIA HELLA is a listed, internationally positioned automotive supplier, known for their lighting technology and automotive electronics. HELLA has more than 36.500 employees at more than 125 locations in 35 countries. One of them is the HELLA Lithuania production plant, located in the Kaunas Free Economic Zone. Since 2018 they manufacture electronic components for the automotive sector, including circuit boards for lighting electronics, actuators for the engine compartment, and fuel pump control units. Currently, the company employs 473 people.

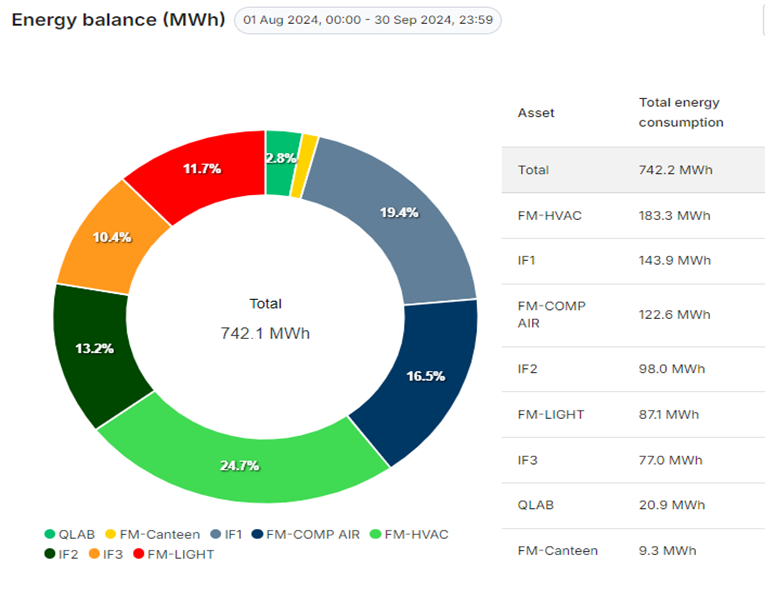

Energy Scouts Paulius Majorovas and Justas Jurgaitis could not overlook the compressed air system, which accounts for 16.5% of the plant’s total energy consumption. The compressed air system at HELLA Lithuania is crucial for powering a wide range of tools and equipment. By driving pneumatic machinery, it supports automation, enhancing both productivity and precision across production processes. Compressed air has many advantages and is widely used in industrial processes but has one disadvantage: generating mechanical compressed air energy from electricity has an efficiency of just five percent. Any minor optimizations in this field will lead to a major impact on energy demand and related costs.

Through the implementation of the “Sensorfact” energy monitoring system, HELLA’s Energy Scouts identified that compressed air systems remain active during non-working days. This results in energy consumption of 793 kWh in 24 hours, which translates to an annual cost of €63.598 based on an average electricity price of €0.22 per kWh solely for air leakages.

The immediate plan involved conducting a comprehensive inspection of the entire compressed air system using a device to find leaks, called “Leak shooter LKS1000-V3+”. The investment of only €3,250 quickly proved worthwhile. With annual savings projected at €63,598, the payback period is just 19 days.

Identifying and repairing the leaks will lead to measurable energy savings. After a detailed inspection of the whole compressed air system in the factory, the Energy Scouts started to optimize the system with the help of their colleagues. In addition, they included the leakage inspection in the preventive maintenance checklist, which is executed every 3 months.

Druckluft

- Industry sector: Automotive industry

- Energy source: Electricity

- Energy savings potential: 289 MWh/year

- CO2 savings potential: 29.5 tons/year

- Potential cost reduction: € 63,598 /year

- Investment costs: € 3,250

- Payback period: 0.05 years = 19 days

- Company:

UAB HELLA Lithuania

Oro Parko g. 6, Karmėlava, LT-54460 Kauno r., Lithuania

https://www.hella.com/en/lithuania-lt.html